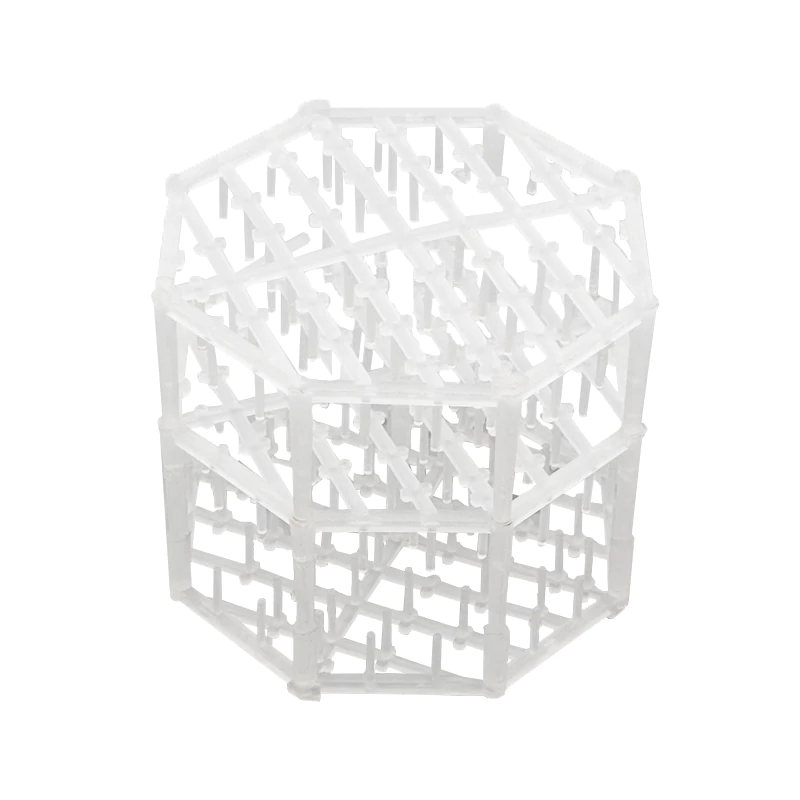

Plastic Q-Pack

CAS NO.: 9002-88-4

Appearance: Hollow ball

Standard Packaging: 0.1 m3 /Plastic bag, , 1 m3/Jumbo bag

Delivery Time : 3-10 days

Quality Insurance: National Standard HG/T 3986-2016

20”GP Load :20-25 m3 40”GP Load: 40-68 m3

CAS NO.: 9002-88-4

Appearance: Hollow ball

Standard Packaging: 0.1 m3 /Plastic bag, , 1 m3/Jumbo bag

Delivery Time : 3-10 days

Quality Insurance: National Standard HG/T 3986-2016

20”GP Load :20-25 m3 40”GP Load: 40-68 m3

Plastic Q-Pack is a kind of high-capacity plastic random packing. It has a special octagonal structure. This structure has a geometric surface, large holes and a small volume. It can ensure plastic Q-pack’s high efficiency in oil-water separation. Plastic Q-pack tower packing has many advantages, such as good plugging resistance, high gas-liquid contacting efficiency, good heat resistance and excellent mass transfer performance. It is suitable for large scrubbers, gas absorbers and coolers.

This type of random packing is easy to operate and install. It has high separation efficiency and low maintenance costs. Plastic Q-pack tower packing is fit for drinking water treatment, wastewater reclamation and biological treatment. It is widely used as filter devices in potable water treatment process, seawater desalination system and VOC (volatile organic compounds) control system.

Material:PE (polyethylene), PP (polypropylene), RPP (reinforced polypropylene), PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride) and PVDF (polyvinylidene fluoride).

Features

Q-pack suitable for use in a lot of different potable water treatment processes, such as:

Drinking water treatment

Q-pack’s large pore volumes and surface areas make it an ideal media for biological treatment of drinking water. Biofilm processes are excellent for treating raw water containing ammonia, manganese, iron etc. Tests have shown that Q-pack works perfectly in these kinds of processes.

In conventional filtration processes Q-pack can be used in different ways. In dual media filters Q-pack can be used in combination with sand. Tests have shown that Q-pack operates as well as or better than traditional filter media in these types of filters.

Q-pack can not only be used in traditional drinking water treatment, but also in treatment of saline water. In desalination plants one of the most important parts is the pre-treatment process. A-pack is an excellent filter media for use in pre-treatment filters in desalination plants.

Effluent water treatment

Q-pack large pore volumes and surface areas make it an ideal media for biological treatment of effluent water. Biofilm processes are excellent for treating water containing nitrogen, BOD etc. Many years of experience has shown that Filtralite is the perfect media for these types of plants.

Q-pack can not only be used in traditional effluent water treatment, but also for odour treatment at sewage treatment works. The porous material is excellent for use in biofilters for removal of hydrogen sulphate and other biodegradable odorous compounds.

Biological filtration

Among the essential parts in the biological aerated filters, (BAF), is the filter media. The biomass that treats organic and nitrogenous matters is fixed to the Filtralite medium, which also works well as a mechanical filter for suspended solids. Filtralite is used both in processes of aerobe systems (nitrification and organic matter) and anoxic systems (denitrification).

Tertiary filtration

As water is a scarce resource in many parts of the world, reuse of water has become more and more normal. To be able to reuse the effluents, tertiary filtration for removal of suspended solids is necessary. The same will be the situation in areas with extra sensitive recipients.

Q-pack has proved to be as good as, or better than, comparable filter media, both in single- and dual media filters. In dual media filters, by replacing the most traditional top layer filter material, anthracite, with Q-pack, time between backwashes can be increased by about 25%. This means fewer stops for backwash and reduced use of backwash water, resulting in more stable operation and lower operational costs.

In single media filters using Q-pack the time between backwashes has been recorded to be up to 4-5 times as long as for filters using sand as filter media.

Q-pack with Filtralite can be operated within a large range of filtration rates. The filtration rate will always be dependent of the configuration of the filter and the treatment process. Filtralite tertiary filters can operate at up to around 15-20 m/h.

In desalination plants it is of great importance for the operation of the entire plant that the pre-treatment of the water is good before the salt is to be removed.

For reverse osmosis (RO) desalination plants a good pre-treatment is essential for avoiding membrane fouling, resulting in reduced water production and increased operational costs.

Q-pack has excellent properties for use in pre-treatment filters in desalination plants, both in filters for filtration of coagulated water and in biological processes. Use of Filtralite will provide low SDI values, reduced danger for bio-fouling of the RO membranes and long filter runs between backwashes.

| Q-PACK | |||||

| Size mm | Void ratio % | Weight Kg/m3 | Bulk Number Pieces/m3 | Packing factor m-1 | Drop points |

| 82.5*95 mm | 96.30% | 33.7kg/m3 | 1165/m3 | 23 | 388 |

Specialist help to select the most appropriate products, calculate the usage amount, offer the best solutions for customers. Providing complete documents to customs clearance in time.

In a full project life cycle, we will provide on-site or web-based engineering support, startup or operation services, technical training and troubleshooting, for your complete project.

Our after-sales team will follow the using effect regularly, if any problem, will offer the suitable method to solve.Providing professional regeneration guidance.

Specializing in the analysis, manufacture, and development of various catalysts, adsorbents, and bed carrier media, we have extensive industrial experience, advanced technology, and process design capabilities to optimize your productivity.

Shenzhen Chem Enviro Technology Co., Ltd is a company specializing in the supplier and manufacture of adsorbents, tower packing, ceramic balls, alumina balls, acid resistant brick, water treatment media.

Copyright © ShenZhen Chem Enviro Technology Co., Ltd. | All Rights Reserved